Technical Overview:

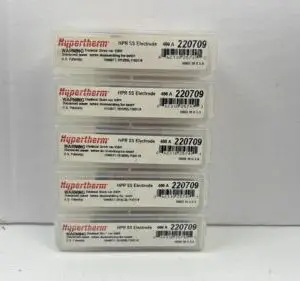

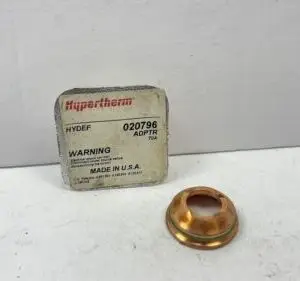

The Hypertherm 45A Nitrogen/Air Electrode is a high-performance plasma cutting consumable specifically designed for stainless steel and aluminum applications. Precision-engineered and made in the USA, this electrode supports nitrogen and air cutting processes, offering exceptional durability, consistent performance, and compatibility with multiple Hypertherm systems, including HD3070, HD4070, HPR130, HPR260, and HPR400.

Key Specifications:

- Brand: Hypertherm

- Amperage: 45 Amp

- Process Gas: Nitrogen/Air

- Compatible Systems:

- HyPerformance HD3070

- HyPerformance HD4070

- HPR130

- HPR260

- HPR400

- Material Applications: Stainless Steel, Aluminum

- Country of Origin: USA

Performance Features:

- Genuine Hypertherm Quality: Ensures optimal performance and reliability.

- Specialized Design: Specifically tailored for nitrogen/air cutting processes.

- Versatile Compatibility: Fits multiple Hypertherm systems for greater flexibility.

- Precision Engineering: Delivers consistent cut quality on stainless steel and aluminum.

- Durability: Optimized for maximum electrode life in high-demand environments.

Construction Benefits:

- High-Quality Materials: Engineered for robust and consistent performance.

- Optimized Gas Flow Design: Supports precise cutting with nitrogen or air.

- Extended Consumable Life: Designed for longevity in high-use scenarios.

- USA Manufacturing Standards: Meets Hypertherm’s stringent quality requirements.

Primary Applications:

- Precision Stainless Steel Fabrication

- Aluminum Processing and Fabrication

- High-Volume Production Operations

- CNC Plasma Cutting Tables

- Automated Cutting Systems

- Custom Metal Fabrication

Technical Capabilities:

- Precise Nitrogen/Air Cutting: Supports clean, high-quality cuts on stainless steel and aluminum.

- Multi-System Compatibility: Works seamlessly with Hypertherm HD3070, HD4070, HPR130, HPR260, and HPR400 systems.

- High-Temperature Resilience: Withstands demanding plasma cutting applications.

Industrial Applications:

- Metal Fabrication Shops

- CNC Cutting Operations

- Industrial Manufacturing Lines

- Custom Metalworking Projects

- High-Precision Cutting Environments

Reviews

There are no reviews yet.