Technical Overview:

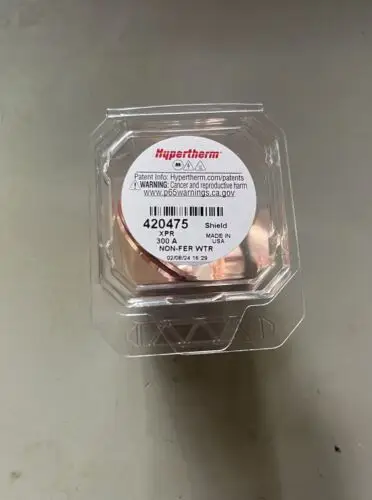

The Hypertherm® 420475 Shield is specifically designed for use with the XPR 300 plasma cutting system, offering high protection and efficiency for non-ferrous material cutting. This shield helps ensure stable arc performance while reducing wear on components, enabling clean and precise cuts on materials such as aluminum, copper, and brass. With its robust construction, the 420475 Shield is optimized for industrial use and is capable of handling high demands for extended periods.

Key Specifications:

- Part Number: 420475

- Current Rating: 300 Amp

- Material Compatibility: Non-ferrous materials (aluminum, copper, brass)

- System Compatibility: XPR 300 plasma cutting system

- Design: Shield for arc protection and performance optimization

- Brand: Genuine Hypertherm®

- Durability: Designed for heavy-duty industrial use

Performance Features:

- High Protection: Safeguards the plasma arc during cutting of non-ferrous materials

- Enhanced Durability: Extended service life for demanding industrial environments

- Efficient Cooling: Reduces the risk of overheating and maintains optimal performance

- Improved Cut Quality: Delivers clean, precise cuts with minimal dross

- Optimized Gas Flow: Ensures proper gas flow for consistent and efficient cuts

- Reliable Performance: Designed for high-volume and continuous cutting applications

Construction Benefits:

- Long-lasting: Built to withstand continuous use in heavy-duty applications

- Gas Flow Optimization: Designed to improve cutting efficiency by optimizing gas flow

- Easy Integration: Compatible with XPR 300 for seamless setup and operation

Primary Applications:

- CNC Plasma Cutting: Ideal for automated cutting systems using the XPR 300

- Metal Fabrication: Suitable for cutting aluminum, copper, and other non-ferrous metals

- Industrial Manufacturing: Used in high-volume production environments

- Precision Metal Cutting: Ensures accurate cuts for professional metal processing

Technical Capabilities:

- Arc Stability: Maintains a stable plasma arc for reliable cutting

- Reduced Wear: Helps protect components from excessive wear, extending lifespan

- Efficient Cooling: Built-in cooling design minimizes heat build-up

- Consistent Performance: Delivers consistent results even under demanding conditions

Industrial Applications:

- CNC Plasma Cutting Systems: Perfect for industrial CNC applications

- Non-Ferrous Metal Processing: Optimal for cutting materials like aluminum and copper

- High-Volume Production: Designed for use in high-output environments requiring consistent, high-quality cuts

Reviews

There are no reviews yet.